The semiconductor shortage isn’t going away anytime soon.

what you need to know

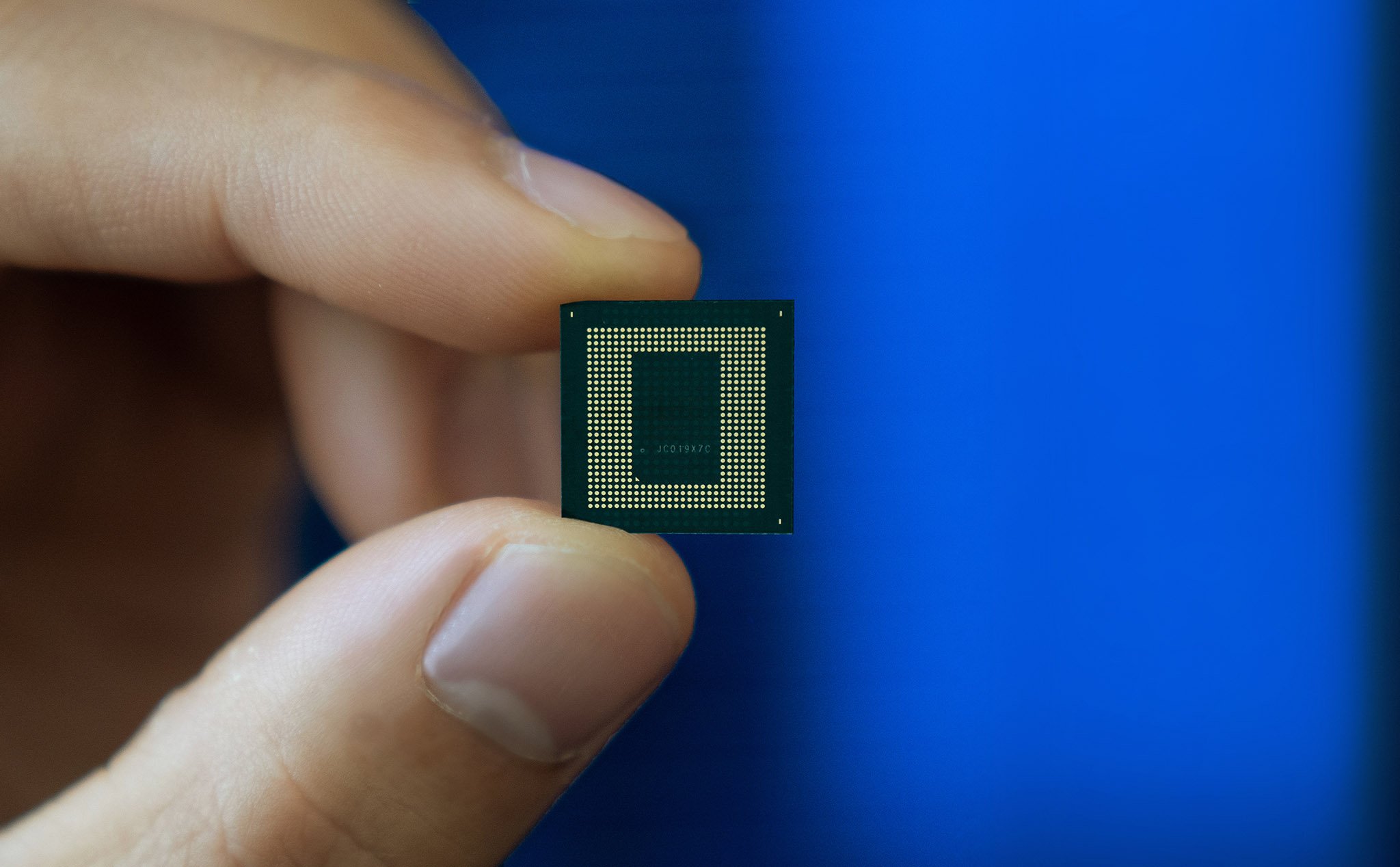

- Since the start of the pandemic, multiple industries have struggled to meet demand due to persistent semiconductor shortages.

- The U.S. Department of Commerce released the results of its investigation into supply chain issues.

- The company cited a number of factors, one of which was a lack of wafer capacity.

- Supply chain issues are expected to continue through 2022 while solutions are being developed.

Anyone who has followed the tech industry over the past few years should be aware that supply chain issues have impacted semiconductor production, with a trickle-down effect across many industries. The U.S. Department of Commerce has investigated the reasons behind these issues and has just released its findings.

The request for information (RFI), launched in September and released on Tuesday, highlights a “perfect storm” of factors leading to supply problems. One of them is the increased demand for things like electric vehicles and 5G, which is seen in today’s best Android phones compared to 2019. This has led to a major shift that the industry is not prepared for, especially in the event of a global pandemic.

Semiconductor manufacturers and companies affected by the shortage responded to the RFI, providing the US Department of Commerce with the following reasons behind the shortage:

The median chip demand highlighted by buyers is 17% higher in 2021 than in 2019, and buyers have not seen a commensurate increase in the supply they receive. This is a serious supply-demand mismatch.

The median semiconductor product inventory highlighted by buyers has declined from 40 days in 2019 to less than 5 days in 2021 (see Figure 2). These stocks are even smaller in key industries.

The main bottleneck across the board appears to be wafer capacity, which requires a long-term solution.

As can be seen from the responses, demand played a big role, but the report also highlighted wafer capacity as the main reason for the shortage.

Since early 2021, several solutions have been put in place to help mitigate the impact of the shortage. Semiconductor companies operate at higher capacity, increase investments, and forge new partnerships. Qualcomm, for example, highlighted in 2021 how it is expanding partnerships to ensure it can meet growing demand for its 5G chips.

Samsung also announced plans to build a $17 billion semiconductor factory in Texas, though it won’t be operational until late 2024 at the earliest.

That said, the report states that despite the changes, “respondents do not believe the problem will go away in the next six months.”

You can read the full report from the U.S. Department of Commerce to better understand the scope of the problem and how to address it, including a proposed $52 billion investment in semiconductor production as part of U.S. innovation and competition law.

Leave a Reply